4-5 Unzen Scientific

Drilling Project (USDP)

The

Unzen Scientific Drilling Project (USDP) is a six-year term project started in

April 1999 following a one-year feasibility study. The project, named

"Unzen Volcano: International Cooperative Research with Scientific

Drilling for UnderstandKyushu University, etc., sponsored by Ministry of

Education, Culture, Sports, Science and Technology (MEXT) of Japan. Geological,

geophysical and geochemical researches on the growth history, subsurface

structure and manner of magma ascent at Unzen Volcano are the principal

subjects of study. USDP consists of two phases (three years each). Phase I

included drilling in two places at the flanks of Unzen Volcano and conducting

associated research to reveal the three-dimensional structure and the growth

history of the volcano. Scientific and drilling strategy for the conduit

drilling and the design were also completed, and a pilot hole for the conduit

penetration was drilled on the northern slope of the volcano. Phase II is drilling

into the conduit of the 1990-95 magmas in order to clarify the ascending and

degassing mechanism of magmas and to evaluate eruption models for the 1990-95

activity. Phase II is being undertaken as a joint research venture with the

International Continental Scientific Drilling Program (ICDP).

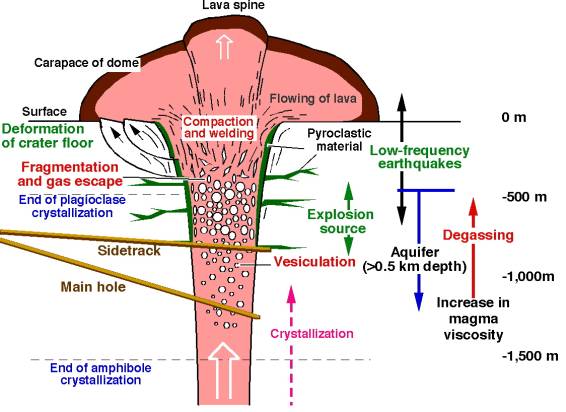

In the

last one kilometer of the ascent, magma is subjected to an order of magnitude

decrease in solubility of water in melt, which is the main reason that

effective degassing occurs in this level (Fig. 1). Degassing of the SiO2-rich

melt and crystallization resulting from the melt's dehydration cause great

changes in magmatic physical properties. Occurrence of swarms of low-frequency

(long-period) earthquakes and evidence for build-up of pressure at shallow

levels just before or during eruption, indirectly help to interpret phenomena

related to the magma's degassing at shallow depth; i.e., in the 1990-1995

eruption at Unzen, isolated tremor events (1.5-0.5 km deep), low-frequency

earthquake events (0.5-0 km deep ), and pressure sources and hypocenters of

vulcanian explosions at 0.8-0.6 km and 1 km-depths, respectively. Direct

drilling into these levels is the best way to, in situ, investigate the

phenomena which accompanied degassing during eruption.

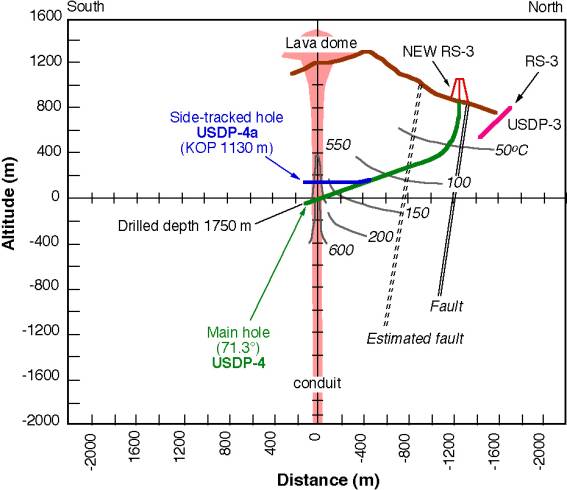

The

geometry of the target conduit is considered to be "dike- (or plate-)

shaped", with a length as large as several hundred meters and a thickness

of 10-20 m. It probably is east-west trending, considering the distribution of

volcanotectonic earthquakes just before eruption, the shape of the lava spine

at the dome-top and the N-S extentional tectonic stress surrounding the Unzen

volcano field. Drilling was started in the northern slope normal to the dike.

The probability to hit the conduit is very high. The seismic experimental data

suggest the location of the dyke in a region having low seismic velocity and no

seismic reflection from horizontally-stratified strata. The normal drilling in

which drilling starts vertically and increases in inclination with depth is the

best choice to drill the hot and challenging target with the lowest risk (Fig.

2). The temperature of the conduit center is estimated as high as 600 °C. However, such

a high temperature is limited to the area close to the conduit. The hole bottom

temperature during operation of conduit drilling can be controlled at rather

low values with a special casing program and mud circulation system, so that we

can use the logging tools (temperature probe, bore hole televiewer, etc) even

at considerable depth in the conduit.

Fig 1

Image of lava dome and upper part of the conduit at Unzen. Effective

degassing from foamy magma occurred during its fragmentation and annealing in

the upper part of conduit. The conduit condition will be investigated in

drilling main hole (USDP-4) in 2003, and continuous coring will be performed by

drilling sidetrack hole (USDP-4a) in 2004.

Fig. 2 Trajectories of

conduit drilling. New RS-3 and RS-3 are drilling sites of main-sidetrack holes

and a pilot hole, respectively.