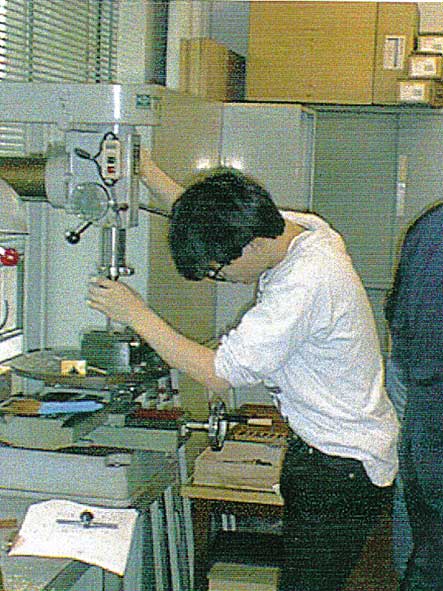

Photo 1. Machining Center "HITOTUBO-KUN".

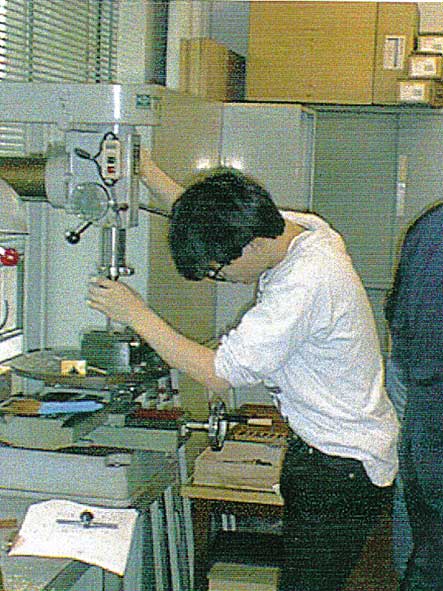

Photo 2. A scene from the short training courses for using machine tools.

1. Maintenance of machine tools and electronic apparatus in the workshop for users.

2. Keeping standard parts such as screws and resistors for users.

3. Manufacturing parts to order from users.

4. Technical consultation with users.

5. Hosting short training courses on using machine tools and designing and building electronic circuits.

6. Development of observational and experimental apparatus with other divisions and / or by ourselves.

The developments of observational and experimental instruments such as seismometers are now proceeding as an inter division and center research project at ERI. To play vital roles in these developments and to improve services for users, the following machine tools and electrical equipment are maintained.

Machine tools: one machining center, four

lathes (with two digital scales), four milling machines (with one digital

scale), three band saws (with one inverter control), one shearing machine,

five drill presses, one digital drillpress, one portable welder, one compact

electro-discharge machine tool, one automatic coil-winding machine, one

high-precision weight scale.

Electronic equipment: six oscilloscopes, five function generators, six digital multi-meters, five dc power supplies, one standard dc power supply, two signal generators, one frequency counter, one FFT analyzer, one LCR meter, two magnetic fluxmeters, one NC milling machine for circuit boards, one laser interferometer system for displacement calibration, one optical power meter, one GP-IB data processing unit.

The machining center and a scene from the short training courses for using machine tools are shown in the photographs below.

Photo 1. Machining Center "HITOTUBO-KUN".

Photo 2. A scene from the short training courses for using machine tools.